Within the dynamic realm of industrial cutting and fabrication, choosing the right cutting method for your project can significantly influence the standard, effectiveness, and cost efficiency of the final product. As businesses strive to optimize their processes and remain competitive, grasping the various cutting techniques at hand is essential. Two popular options that have earned traction in recent years are laser and water jet cutting services. Each method brings its specific unique advantages and is suited for different materials and applications.

Choosing the correct cutting method requires careful consideration of aspects such as material type, thickness, tolerance standards, and production volume. By gaining insight into the characteristics of laser and waterjet cutting, manufacturers can make informed decisions that will enhance their operational capabilities. In this guide, we will explore the key distinctions and benefits of these cutting methods, assisting you to find your way through the choices available and effectively meet your project requirements.

Comprehending Trimming Methods

Upon initiating an manufacturing trimming assignment, it is essential to understand the various slicing techniques available. Each technique has distinct characteristics that may be preferably suited for certain materials and applications. The choice of slicing technique will significantly affect the efficiency, caliber, and cost-effectiveness of the final product. Two frequently employed cutting methods in the industry are LASER and water-jet slicing services, both providing unique benefits and applications.

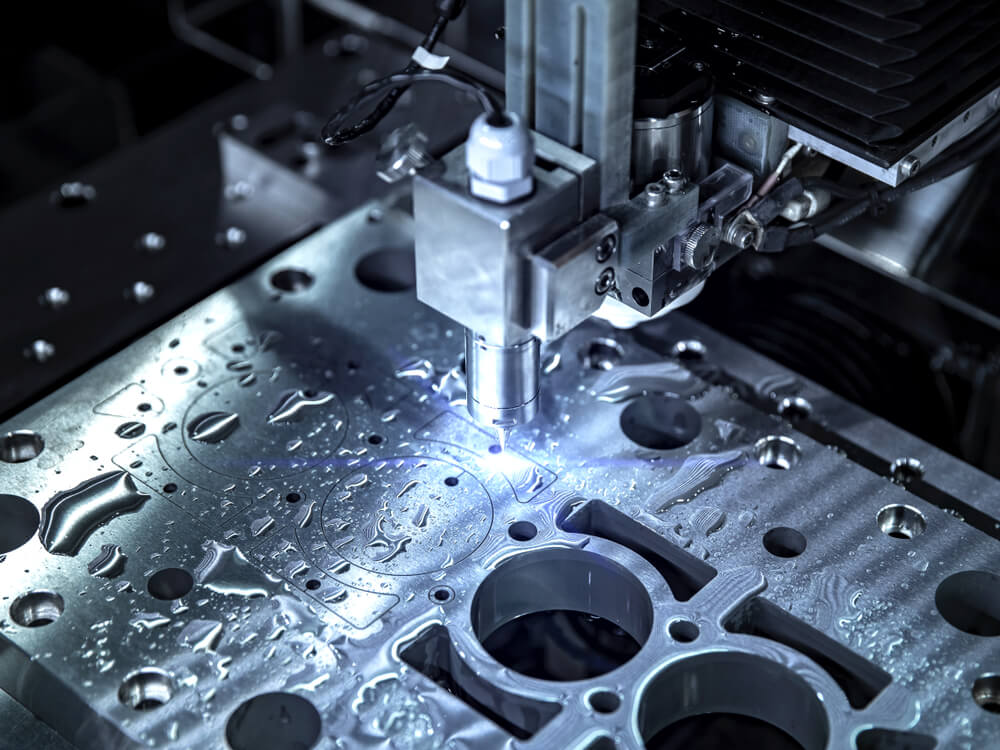

Laser cutting uses directed beams of light to precisely slice through materials. This method is well-known for its precision and capability to create complex designs. It is commonly used on materials such as metal, plastics, and timber. Laser technology allows for minimal heat impact, reducing warping and ensuring neater edges. Additionally, the quick functioning of LASER cutting makes it an excellent choice for tasks requiring rapid production times without compromising quality.

Conversely, hydrojet cutting employs a high-pressure stream of water, commonly mixed with abrasives, to slice through multiple substances. This technique is particularly advantageous for denser materials and can trim through metals, crystal, rock, and composites. Waterjet cutting is appreciated for its capability to work without creating heat, thereby protecting the material's structure. Furthermore, it generates no toxic fumes, making it a more secure option in numerous industrial settings. Understanding these distinctions is crucial for selecting the slicing method that aligns with your task's specific requirements.

Benefits of Laser Cutting

This cutting method offers exceptional precision, making it suitable for intricate designs and elaborate shapes. The concentrated beam of light facilitates for smooth cuts with minimal kerf, ensuring that the material removed is restricted. This level of precision not only elevates the overall quality of the product but also decreases the need for secondary finishing processes, conserving time and resources in fabrication.

Another significant advantage of laser cutting is its adaptability. It can be used on a variety of materials, including metal, polymer, timber, and clay products. This adaptability means that businesses can adapt to various project requirements without needing invest in various cutting technologies. Furthermore, laser cutting systems can easily change between materials, allowing for rapid changes in production runs while ensuring high efficiency.

Efficiency in costs is also a key benefit of laser cutting. Although the initial investment for laser cutting machines might be more significant compared to old-fashioned cutting methods, the sustained savings are considerable. With lessened material wastage and decreased labor costs due to the automatic nature of the process, companies can see a significant return on investment. Additionally, the velocity of laser cutting can lead to quicker lead times, which is essential in cutthroat manufacturing environments.

Advantages of Waterjet Cutting

Water jet cutting offers a elevated level of accuracy, making it an excellent choice for tasks that demand intricate designs and stringent tolerances. The method utilizes a pressurized stream of fluid, often mixed with abrasives, which can easily cut through a variety of substances, including metals, polymer-based materials, and ceramics. This feature allows for clean edges and little material wastage, which is important in commercial cutting and fabrication.

Another key advantage of water jet cutting is its flexibility. It can handle a broad range of workpieces and thicknesses without switching tools or configurations. This capability makes it ideal for various purposes, from model making to extensive production runs. Additionally, because laser and waterjet cutting service does not produce heat, it reduces the likelihood of changing or modifying the structural integrity of temperature-sensitive materials.

Waterjet cutting is also an sustainable option as it uses liquid as its principal cutting medium, and produces minimal hazardous waste. The nonexistence of harmful emissions means it can be employed in industries that prioritize eco-consciousness. In industrial settings where adherence with eco-laws is important, water jet cutting stands out as a viable and accountable choice.